We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

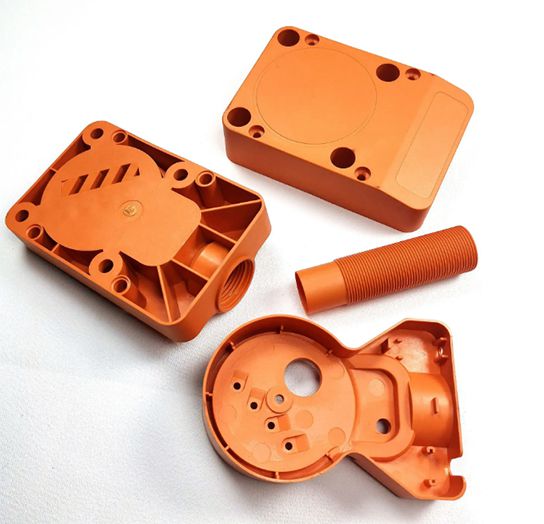

If you want to assemble plastic parts together or assemble plastic or metal parts with machine part, screw, or baring, KaierWo ENGINEERING can serve your needs either component will be supplied by you, or will be sourced by Kaierwo Engineering.

Assembly is the act of joining metal components into plastic or other mating parts through processes such as riveting, binding with adhesives, threaded fasteners, and more. In most manufacturing processes, metal assembly requires both automation and human labor. There are several types of metal assembly in manufacturing. These include

1.Mechanical Assembly

Assembly testing relates to whether the product funclion can perform as what it is

designed for. We can offer mechanical assembly which involves all kinds of fastners such as nuts, screws and bolts etc. and we can also do threaded inserts, press fitting and riveting.

2.Professional Technicians

When we start to manufacture the prototype or to mass production for customer our professional technicians will perform assembly tests according to customer's assemblydrawings and requirements.

3.After-sales Guarantee

If there is on assembly problem, we will inform the customer immediately, then provide solutions and obtain the customer's approval.

4.Our Promise

Our aim is to provide assurance for the functional product quality and that will save

the customer's valuable time.

We have been cooperating with VOWG,GREE and MINDRAY since 2014. We help our customers with the design and manufacture of the main assembly components (plastic parts, die casting parts, aluminum profiles, and outer package) and the sourcing of other components,they received products and gave unanimous praise.

Assembly service helps our customers save cost and time on their projects. From mold production to mass production, to product assembly and packaging, product materials range from rubber, plastic to metal, Kaierwo's one-stop service will continue to improve to meet all your needs.

Made to order from 1 to 10,000 pieces on demand

One-on-one support serviceOResponse within 12 hours

In-house machine shop, 24/7 operations, Quick turnaround

Tight tolerance +0.05mm Surface roughness Ra0.2μm

ISO 9001:2015 certified100% part inspection

Saving Your Time

The lead time is 40% faster than other factories.

Advanced equipment and efficient production process——faster manufacturing and shorter lead times.

Effective communication on product solutions by experienced engineering team—— quick response within a few hours.

Saving Your Cost

You will save20-30% of the cost

14 Years focused on Prototyping And Manufacturing with extensive industry experience - - excellent production capacity and cost control system

One-stop service will shorten your supply chain-----fast turn around product

Reduce Your Risk

You will reduce risk and 70% works

Professional inspection department and testing equipment (CMM,flash tester,profiler)-quality is guaranteed

One-stop service will shorten your supply chain-----fast turn around product

Non Disclosure Agreement available.

FAQ

Can KAIERWO make design drawings for me?

We don't provide design services. You are responsible for submitting 2D and 3D CAD drawings, and we can then provide a Design for Mant facturing review upon receiving your order.

How do l know my design will be kept confidential?

We of course will sign and adhere to any non-disclosure or confidentiality agreement. We also have a strict policy within our factory that no photographs are ever lwed of a customers product without express permission. Ultimately we rely on our reputation of working with hundreds of thousands of unique designs over many years and never allowing any proprietary information to be disclosed to a third party.

How to ship? What about the packing details?

For small quantity, we have cooperation with TNT, FEDEX, UPS etc.

For big quantity, air or sea would be available for you to choose.

We attached our normal packing details. If you have any special requirements, we would be willing to help.

Does the company have the capacity for mass production?

The company has independent production and large-scale production conditions, one-stop service,70 CNC machine tools,40 injection molding machines, and has its own mold workshop.

How to avoid mass order quality problems?

Strengthen the prevention and inspection in advance of the process of production and processing, set important processes as the key point of quality control, follow up the inspection and defense throughout the process.

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!