We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!

+86 133 9281 9446

Low volume manufacturing

Low volume manufacturing usually refers to smaller production quantities, which may be tens to thousands of pieces, to produce a small number of products in a short period of time, depending on the industry and the type of product, according to customer demand or market changes. This type of production is more flexible and can respond quickly to market demand and meet the requirements of customised production or pilot production.

Low volume manufacturing enables enterprises to better adapt to market changes, meet customers' individual needs, reduce inventory risk and improve capital turnover efficiency. In addition, low volume manufacturing also provides enterprises with the opportunity to conduct exploratory sales in the market and verify new product designs. Through low volume manufacturing, enterprises are able to enter new markets with lower risks and costs, and enhance their competitiveness.

View All

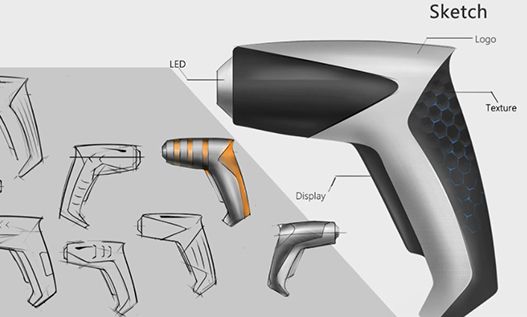

Great designs don't just appear overnight – they take time to get right. in fact, all other kinds of designer know that they don't get one try to make a product the best it can be, it takes many iterations to get the product the way that it best suits the user.

Between design iterations, it is necessary to rapid prototyping small batch manufacturing, the fastest time to convert the design into a finished product, based on the finished product again to improve, again manufacturing, and ultimately get the most in line with the expected results!

View All

New products mean new business opportunities in the market, so it is necessary to occupy the market as soon as possible, seize business opportunities, open up the popularity of products, and lay a market foundation for products

When a new product design comes out, there is definitely not a lot of market demand in the early stage. It takes time to open the market slowly. At first, it is only suitable for small and medium batch processing to meet the market demand. The cost will not be too high

One or several plastic products require dozens of sets and hundreds of sets to be produced in small batches. The cost of build a steel mold cost too much, which is very uneconomical, and the waiting time is relatively long. For new products, time is money, and it is necessary to Carry out various verifications in the early stage as soon as possible. At this time, prototype low volume production will come into play.

About Kaierwo

We are committed to providing you with one-stop service from 1+ prototype to 100,000 + production, serving in electronics, automotive, robotics, biological and medical equipment, defense and space industry. Detection and testing is also very strict, detection equipment including CMM, 3D scanner, calipers, inclinometer, micrometer, pin gauge, hardness tester and so on. We also test assembly according to customer requirements to meet customer needs. Kaierwo strives to provide you with the best customer experience and qualified products in accordance with ISO 90001 and ISO 13485.

14years

Industry Experience

150+

Dedicated Employees

6000+

Square Meters of Factory

40000+

Projects Delivered

The main overseas markets are: The United States, Canada, the European Union, Mexico, Brazil, Japan, Korea, Singapore, the Middle East, Australia. At present, we have established long-term business relationships with more than 50 companies in more than 20 countries. Your satisfaction is our wish, we warmly welcome your presence.

We attach great importance to customers' needs for product quality and rapid production.

We always insist that meeting customers' needs is to realize our value!